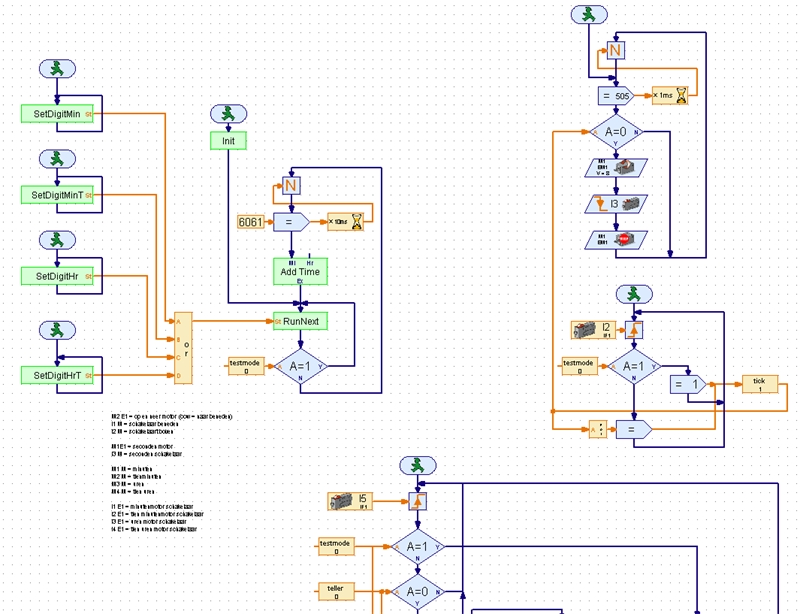

ROBOPro Program

Hochgeladen am 7.3.2016, 12:45 von winijenh. 15 / 16

The clock driven by a ROBOPro program running on the TX controllers. 60610 milliseconds on the internal TX clock is about a minute, and every minute, the program calculates the segments that need to change, and lowers the carriage to make the changes.

Stefan Falk (7.3.2016, 15:27:30)

This is an exceptionally well-engineered and built, fantastic model. Congratulations! I have two questions:

a) “60100 milliseconds on the internal TX clock is about a minute” sounds funny. Is this the case on all TX controllers, or by chance just on yours?

b) Is that fine gear wheel robust enough to transport the mechanics (with 2 S-Motors) up and down reliably? Even if the model is running for days or weeks?

My deep respect for this superb work.

Stefan

winijenh (7.3.2016, 16:26:09)

a) Actually the number s 60610ms (as you can see in the ROBOPro program). I have tried this on a at least 2 TX Controllers, and they are consistent. b) Yes it is. I was surprised about it, frankly. I have tried various different things, including the use of the regular ‘Hubgetriebe’. The problem with that is that you need two motors and it is impossible to keep them synchronised. So I had to use a single shaft to connect both sides. Two ‘Führungsplatte für Elektromagnet’ keep the gear wheels really snug against the Zahnstange.

Willem Evert.

Dirk Fox (8.3.2016, 10:34:28)

What about connecting a DCF77 receiver to this wonderful clock? (https://www.ftcommunity.de/details.php?image_id=35259) Regards, Dirk

winijenh (8.3.2016, 13:55:45)

Yes, that would be nice. In fact I wrote a Bluetootth integration for the TX to get time from a PC. I can also be used to put other texts on the displays. Or use two TXTs or course which have time themselves, but I started building this model before the TXT was even available ;)